| 04/03/2018 16:26:30~~~~~~emilywong |

Coals |

Thermal coal is used in combustion processes to produce steam for power generation, heating, and industrial applications such as cement manufacture. Thermal coal can be further sub-divided into different market tiers based on energy content. The following energy bandings for thermal coal are used in this report:

Metallurgical coal is used in steel production. It is used either to produce coke, which is then fed into the top of the blast furnace along with the iron ore; or for pulverized coal injection, where the coal is injected directly into the base of the blast furnace. Metallurgical coal is classified based primarily on the strength of the coke it produces. Only a limited range of coals—specifically bituminous coals that exhibit plasticity and swelling—produce good quality cokes. The common metallurgical coal classifications are: Hard coking coal (“HCC”). These coals have the ability to make a strong (hard) coke when coked alone in a conventional coke oven, although the quality of coals fitting this definition can vary significantly. Premium HCC has the highest coke strength indices and so attracts the highest prices. In some markets HCC is further classified as high volatile (“HV”), medium volatile (“MV”) and low volatile (“LV”). Semi-soft coking coal (“SSCC”). These are coals that do not produce a coke with sufficient strength to meet blast furnace requirements when coked alone, but that nevertheless have value as a coke oven blend component. The precise blend of coals used will determine the quality of the coke produced. Blending is desirable as it reduces the overall cost of coke production, but there is a limit to the proportion of SSCC that can be added without a negative effect on coke quality. Pulverized coal injection (“PCI”) coal. The use of PCI coal, which is injected directly into the base of the blast furnace, lowers consumption of expensive coking coals; PCI coals are therefore ranked by their ‘coke replacement ratio’. Various coal types can be used successfully for PCI, but they generally fall into two broad Information Memorandum categories: (1) ultra-low volatile (“ULV”) semi-anthracites, and (2) HV lower ranked bituminous coals such as SSCCs. The semi-anthracites have a high fixed carbon content—and hence a high coke replacement ratio—making them especially attractive for this application, especially the lower cost fines. A low ash content isalso preferred for PCI coals. |

| 18/01/2018 03:14:33~~~~~~manpakhong |

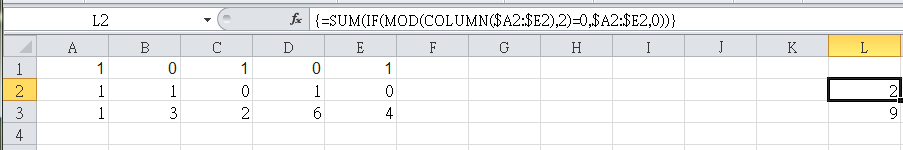

Excel - sum alternate column |

=SUM(IF(MOD(COLUMN($A2:$E2),2)=0,$A2:$E2,0)) - press alt+shift+enter

For even column index: Column B, D 's index are 2, 4. so that mod(2,2) = 0, mod (4,2) = 0. then using array function to sum it up. For odd column index change the mod(column_index, 2) <> 0, =SUM(IF(MOD(COLUMN($A2:$E2),2)<>0,$A2:$E2,0)) - press alt+shift+enter |

| 17/10/2017 03:24:48~~~~~~manpakhong |

Android app locale - for Hong Kong res folder |

Android app locale - for Hong Kong res folder The locale folder for res/values is a little bit complicated and confused for most of the developers. For Hong Kong, it has different Chinese version even the same region. In order to have a correct method to provide the language, the following is listed for the resource folder naming. res/values-zh (Traditional Chinese - Hong Kong) |